Cutlery is a term that today is used to group together different items, including knives, forks and spoons that are used at the table for eating and serving rather than the utensils used in the kitchen. However traditionally cutlery in Sheffield was only knives, made by a Cutler who only makes items that cut, which is still the tradition in our factory. Spoons & forks were called flatware but more recently the term cutlery has become all embracing for knives, forks & spoons.

The vast majority of cutlery today is made with stainless steel, especially in the hospitality industry because it is best for everyday use since it’s affordable, durable, and easy to care for. Cutlery can also be made of silver-plate or even sterling silver, which is where the term silverware comes from. However, silverware is not recommended for general commercial use but silver-plate is still used in fine dining restaurants and hotels.

Let’s concentrate here on the various types of Stainless Steel used in cutlery manufacturing.

There are four different grades of stainless steel commonly used in the manufacture of cutlery: 18/10, 18/8, 18/0, and 13/0. These numbers refer to the percentages of chromium and nickel in the stainless steel alloy. Chromium is used in to provide durability as well as resistance to rust and corrosion, while nickel is used to give cutlery its strength. So, for example 18/10 means 18% chromium and 10% nickel and is the best quality and is what we as genuine manufacturers use for our Chimo cutlery. 13/0 on the other hand is the lowest quality with only 13% chromium and no Nickel – so little strength – like Yuri Geller’s spoons.

To see our range of 18/10 stainless steel cutlery patterns click here

We need to stop here to discuss knives because knives are very different from spoons & forks.

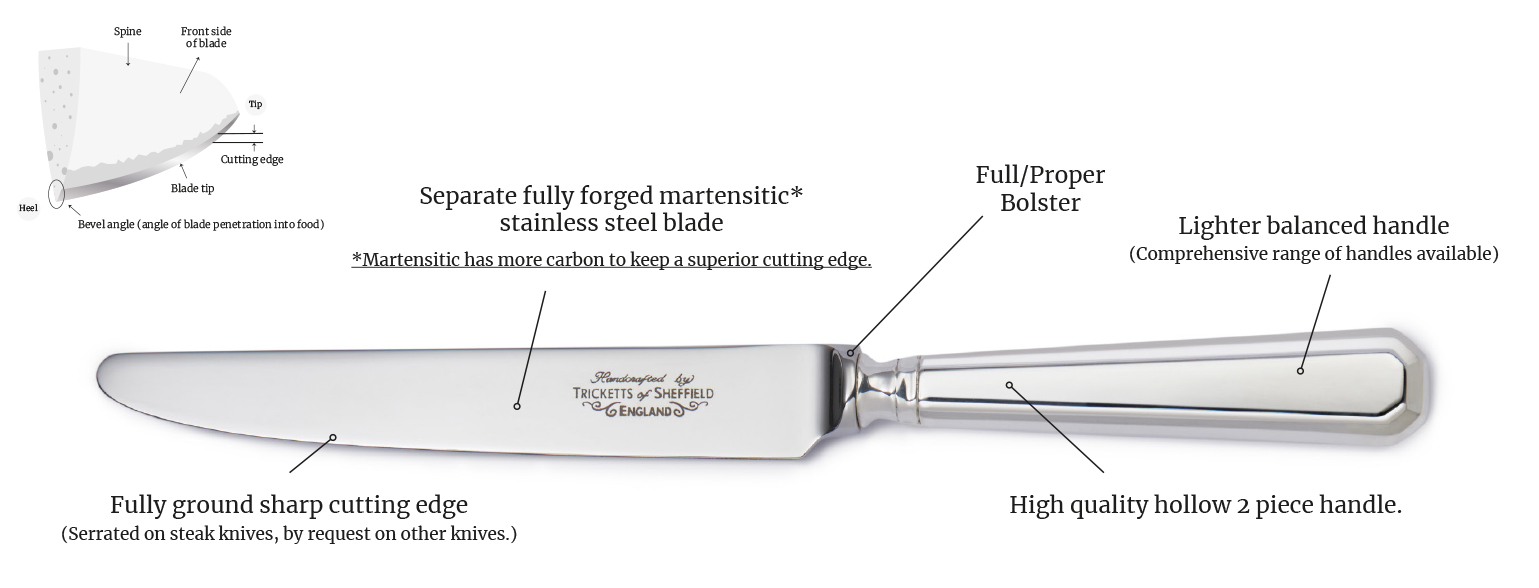

Any quality knife should be made of two parts with a blade firmly attached to a separate handle. This is so the blade can be forged in martensitic stainless steel, a special quality stainless steel specifically made for blades, containing a higher level of carbon so the blade can have, and retain a superior cutting edge.

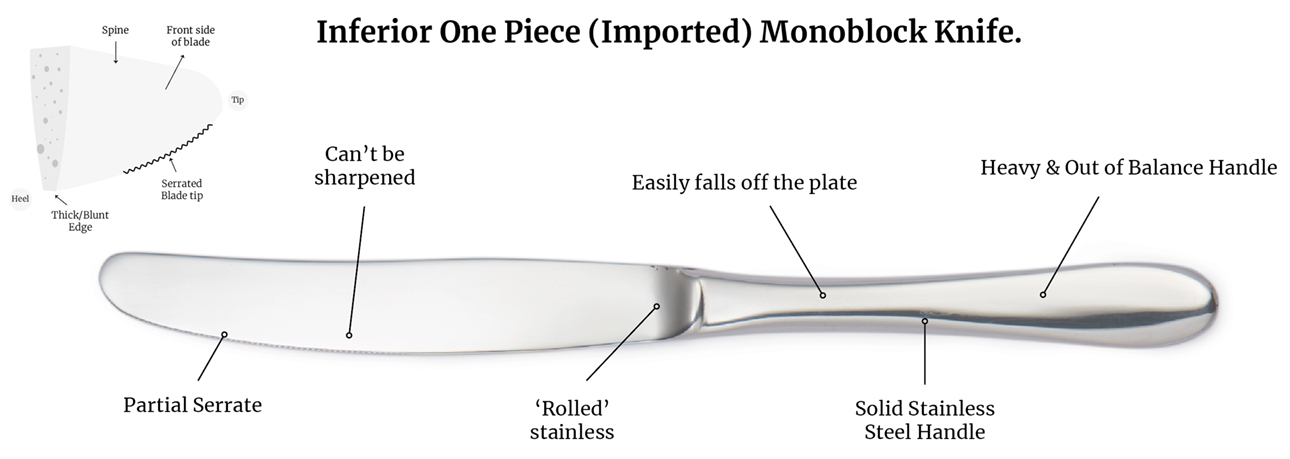

Virtually all imported knives these days are one piece or monobloc knives (see below) with completely out of balance heavy** handles, but more importantly inferior quality blades. Monobloc knife blades are rolled and stamped out of the same standard stainless steel as the handles and at very best this can only be 18/0 or more often 13/0 steel. This lower grade of stainless cannot be sharpened, so they put a thin serrate in the blade which at best can only tear the meat apart.